About Us

Armor Canada Co., Ltd. is a high-tech company engaged in the development, production, sales and service of anti-corrosion and wear-resistant special petroleum equipment and accessories. We provide customized solutions and a wide range of wear and corrosion resistant products for premature failure of carbon steel pipes and fittings in the process of oil and gas production due to the harsh and complex underground corrosion environment.

Process Introduction

The Armor surface alloy layer uses a special process unique to our company to penetrate a variety of metal elements into the carbon steel substrate to form a new ordered solid solution phase layer based on metal compounds on the surface of the carbon steel. The alloy layer crystal structure is dense, with high corrosion resistance, high wear resistance, high temperature oxidation resistance and other characteristics, can effectively extend the service life of carbon steel pipes and accessories, reduce the product failure caused by frequent shutdown maintenance, greatly reduce production costs, improve mining income.

Product Category

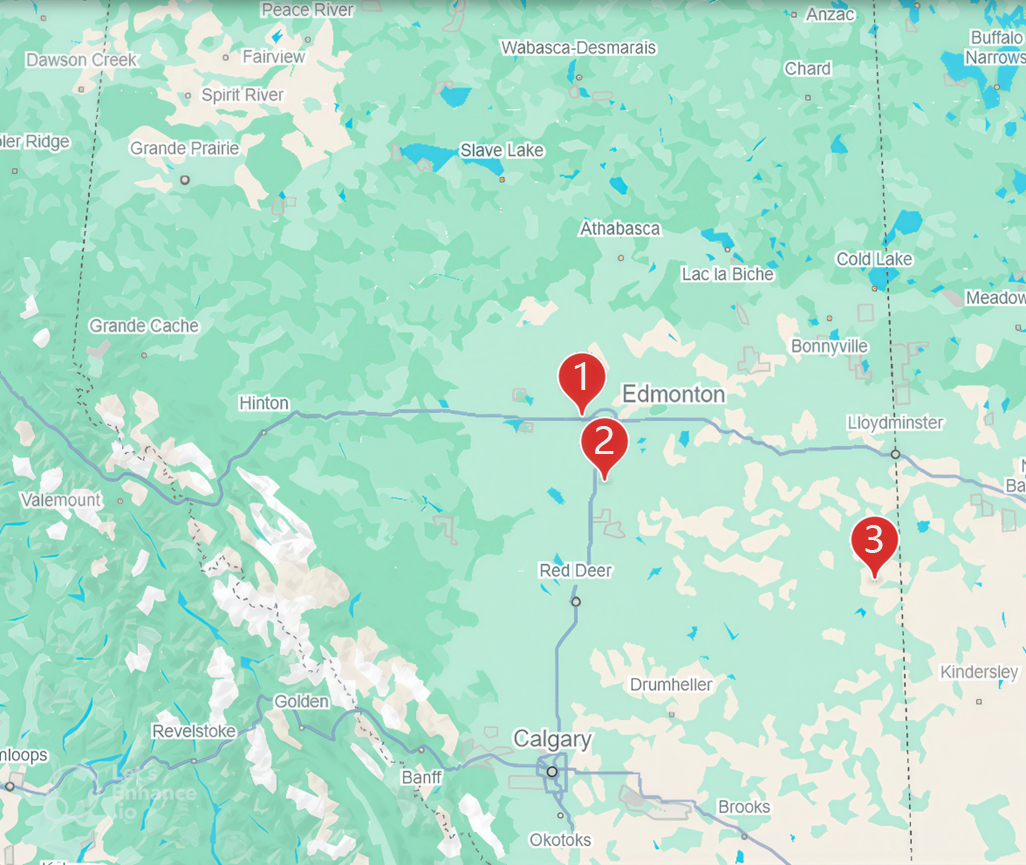

Warehouse

We have currently established multiple warehouses in Canada to allow customers to conveniently pick up goods nearby.

Contact

Tel

+1 825 983 6987Specifications

HIC and SSC resistant for high H2S oil and gas wells;

Pitting resistance, suitable for high CO2, Cl- oil and gas wells;

High temperature oxidation resistance 700℃/1292℉, suitable for high temperature wells;

The alloy layer is integrated with the carbon steel substrate, without delamination peeling phenomenon, and has good toughness and ductility;

Basically do not change the pipe diameter, improve production efficiency;

Meets APT 5CT/5L standards

Specifications

High surface hardness, erosion resistance, suitable for high sand oil and gas production;

Prevent rod deviation and lateral load wear, suitable for deviated wells and PCP lifting process;

Corrosion resistant, suitable for high CO2 and Cl- oil and gas Wells;

Reduce the friction coefficient of the inner wall of the tubing and keep the fluid transfer efficiency high;

Meets APT 5CT/5L standards

Specifications

Effectively resist the erosion and pitting perforation of formation minerals and underground high salinity water;

Effectively prevent pitting, etching and erosion of inner wall by gas and liquid phase containingH2S, CO2, Cl-;

High temperature oxidation resistance 700℃/1292℉, suitable for high temperature deep wells;

Due to the alloying treatment of both inner and outer walls of the casing, its service life will be greatly extended;

Meets APT 5CT/5L standards;

Specifications

High surface hardness reduces abrasive wear caused by gravel in drilling mud to the barrel surface;

Resist the mechanical wear of barrel surface caused by abnormal movement such as plunger offset wear;

Excellent corrosion resistance to a variety of corrosive media, suitable for drilling operations under high H2S, CO2 and Cl- geological conditions;

The alloy layer and barrel substrate are metallurgically bonded without delamination or peeling;

Suitable for harsh environment operation such as high temperature and high pressure;

Specifications

High surface hardness provides strong protection against wear and erosion caused by sand bearing fluids;

Excellent corrosion resistance to various corrosive media, suitable for oil and gas wells with high H2S, CO2 and Cl- content;

The alloy layer and rotor substrate are metallurgically bonded without delamination or peeling;